Alaabta

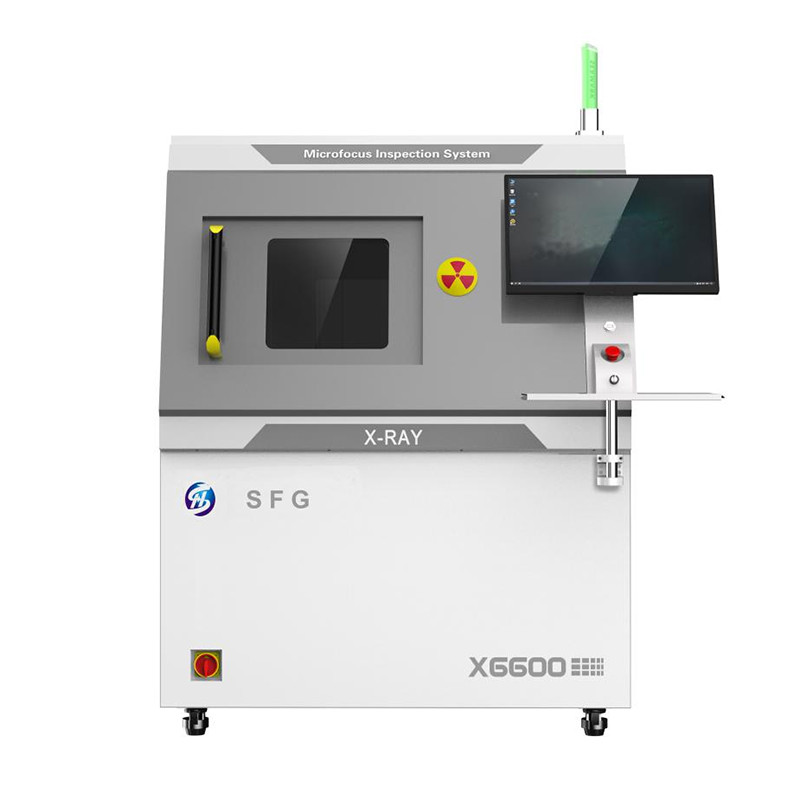

X-Ray Solution X6600 Soo saaraha Nidaamka Kormeerka X-ray ee Microfocus

Faa'iidada

| 1: Semiconductor | 2: Gawaarida Elektarooniga ah | 3: PCB'A | 4: LED |

| 5: Kormeerka BGA/QFN | 6: Aluminium dhinta shubka | 7: caaryada | 8: Qaybaha korontada iyo farsamada |

| 9: Abuurka beeraha noolaha | 10: Qaybta duulista | 11: Hubka giraangiraha | 12: Silig/USB/Plug |

Hawlaha iyo Tilmaamaha

| Shaqada | Faa'iidooyinka |

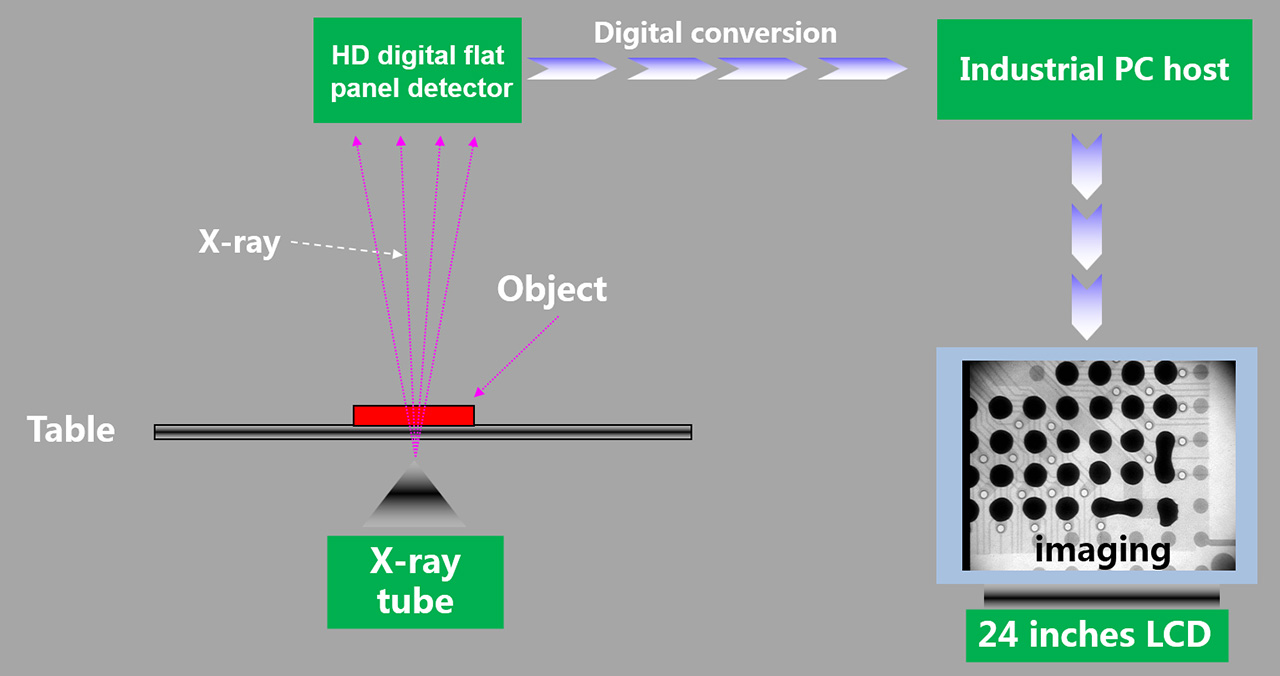

| Tuubbada raajada iyo qalabka wax baadha waxay u dhaqaaqi karaan jihada Z, Xawaaraha miiska u socda jihada XY waa la hagaajin karaa. | Kala duwanaansho wax ku ool ah oo weyn, hagaajinta weyneynta iyo hufnaanta sheyga. |

| Qalab-sheege heer sare ah oo dhijitaal ah Xagasha ugu sarreeya waa 65°, muunado waxaa lagu arki karaa aragti gaar ah | Way fududahay in la aqoonsado cilladaha dhinaca alaabta oo aan la helin ogaanshaha xagal dhintay. |

| Tuubbada raajo nolosha dheer, dayactirka nolosha oo bilaash ah | Qaado isha ugu sareysa ee Jabbaan Hamamatsu X-ray |

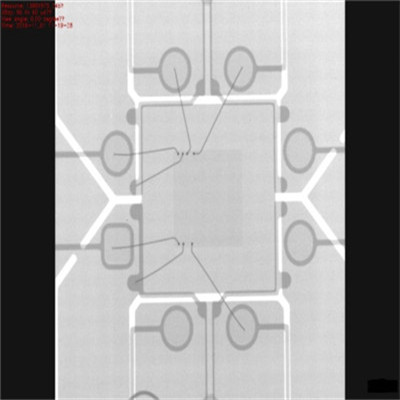

| Cilad ka yar 2.5μm waa la ogaan karaa.Ogaanshaha sare ku celi saxnaanta. | Si fudud loo kala saaro foorarsiga fiilada dahabka iyo jebinta xirmada semiconductor. |

| Shaqada Cabbirka CNC ee xoogga badan, si toos ah ayey u tijaabin kartaa, barnaamijka tijaabada waa la tafatiri karaa. | Ku habboon kormeerka ballaaran oo wanaajinaya waxtarka ogaanshaha. |

| Meel ballaadhan oo kormeer ah, waxay ku dhejin kartaa muunado kala duwan oo waaweyn.Miisku waxa uu qaadi karaa 10KG. | Miis weyn oo loogu talagalay looxyada kantaroolka warshadaha ee waaweyn, xargaha LED-ga aadka u dheer, iyo alaabada elektiroonigga ah ee dhinacyada kala duwan |

| Aragtida navigation weyn, miiska u dhaqaaqi doonaa meesha aad gujiso jiirka. | Aad bay u fududahay in la shaqeeyo, si dhakhso leh u hel cilladaha sheyga oo hagaajiso waxtarka ogaanshaha |

Halbeegyada Farsamada ee Hardware

| X-Ray Solution X-6600AHalbeegyada farsamada qalabka | ||||

| H A R D W A R E | Tuubada X-RAY

| Nooca tuubada | Tuubbada raajada microfocus ee xiran | |

| Voltage Tube | 40-90kV | |||

| Tube hadda jira | 10-200uA | |||

| Cabbirka barta fooqa | 5-15μm | |||

| Habka qaboojinta | Qaboojinta isku-dhafka | |||

| Baaraha | Nooca baaraha | HD baadhisaha fidsan dhijitaalka ah (FPD) | ||

| Goobta sawirka | 130mm*130mm | |||

| Matrix Pixel | 1536*1536 pixels | |||

| Xagasha u janjeerta | 0-60° | |||

| Xawaaraha kormeerka iyo saxnaanta | Xaqiijinta imtixaanka soo noqnoqda | 3μm | ||

| Xawaaraha baadhista software | 3.0s/dhibic (marka laga reebo wakhtiga rarida iyo dajinta) | |||

| Miis | Cabbirka caadiga ah | 540mm*440mm | ||

| Aagga kormeerka waxtarka leh | 500mm×410mm | |||

| Awoodda culeyska | ≤5Kg | |||

| Barnaamijyada CNC | Qiyaasaha tijaabada ee alaabada kala duwan waxaa lagu kaydin karaa qaybo waxaana la waci karaa wakhti kasta.Waxaad dejin kartaa dariiqa ogaanshaha ama isku xigxiga hal ama in ka badan oo alaab ah, barnaamijkuna wuxuu si toos ah u dhammaystirayaa ogaanshaha oo kaydiyaa sawirrada. | |||

| Madal shaqaynaysa | Mouse, kiiboodhka, 2 hababka hawlgalka | |||

| Shell | Saxanka rasaasta gudaha | 5 mm qaro weyn saxan sunta rasaasta ah (shucaac gooni ah) | ||

| Cabirka | 1360mm (L) * 1240mm(W) * 1700mm(H) | |||

| Miisaanka | 1250Kg | |||

| Halbeegyada kale | Kombiyuutarka | 24 inch Widescreen LCD/I3 CPU/2G Memory/200G Hard Disk-ga | ||

| Korontada | AC220V 10A | |||

| Heerkulka iyo qoyaanka | 22±3℃ 50%RH±10%RH | |||

| Awoodda guud | 1700W | |||

| Badbaadada | Heerka badbaadada shucaaca | Qabo qaab dhismeedka ilaalinta birta-lead-birtaMeel kasta oo 20mm u jirta qolofka, shucaaca≤1μSV/H, oo waafaqsan heerarka caalamiga ah | ||

| Shaqada isku xidhka badbaadada | Laba daaran oo xaddidan dareenka sare ayaa lagu dejiyay booska furitaanka albaabka si loogu dayactiro qalabka.Marka albaabka la furo, tuubada raajada ayaa si toos ah u dami doonta isla markiiba. | |||

| Ilaalinta beddelka elektromagnetic | Daaqadda wax lagu eegayo waxa ay leedahay furaha korantada (electromagnetic switch), daaqada wax arka lama furi karo marka tuubada raajada ay ku jirto xaalad shaqaynaysa. | |||

| Daaqada indho-indheynta | Daaqadda fiirsashada, muunada waxaa si toos ah looga arki karaa daaqadda marka mishiinku socdo. | |||

| Joogsiga degdega ah | Joogsiga degdega ah wuxuu ku yaalaa booska caanka ah ee qalabka konsole-ga iyo qalabka, waa la cadaadin karaa si dhakhso ah loo gooyo nidaamka korontada. | |||

| Tuubada raajada ilaalinta tooska ah | Shan daqiiqo ka dib markii mishiinku aanu shaqayn, tuubada raajada ayaa si toos ah u dami doonta oo geli doonta xaalada ilaalinta. | |||

| Ilaalinta mashiinka otomaatiga ah | Marka albaab kasta ama daaqad kasta oo mishiinka la shido, mishiinku isla markiiba waxa uu galaa xaaladda ilaalinta xidhitaanka, wax qalliin ah lama samayn karo. | |||

Halbeegyada farsamada software

| X-Ray Solution X-6600AHalbeegyada farsamada software Software-ka falanqaynta sawirka raajada oo si buuxda u sifaysan, oo ay ku jirto kor u qaadida isbarbardhigga sawirka iyo hawlaha shaandhaynta, hawlaha cabbirka, iyo barnaamijka CNC | |||

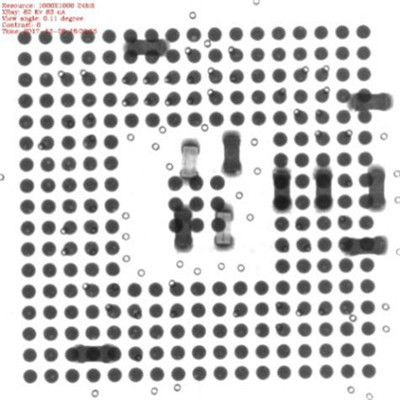

| S O F T W A R E | Xukun alxanka xun | BGA gaaban | Sawirada NG-ga ee hore loo dejiyay, softiweerku wuu ka duwan yahay oo si toos ah ayuu u aqoonsanayaa |

| Alxanka qabow ee BGA | Sawirada NG-ga ee hore loo dejiyay, softiweerku wuu ka duwan yahay oo si toos ah ayuu u aqoonsanayaa | ||

| BGA ma bannaana | Sawirada NG-ga ee hore loo dejiyay, softiweerku wuu ka duwan yahay oo si toos ah ayuu u aqoonsanayaa | ||

| BGA alxan been ah | Sawirada NG-ga ee hore loo dejiyay, softiweerku wuu ka duwan yahay oo si toos ah ayuu u aqoonsanayaa | ||

| Shaqada CNC | Habka Motion Programming (CNC) | Xuduudaha tijaabada ee alaabada kala duwan, waa la kala saari karaa oo la kaydin karaa, wac wakhti kasta | |

| Wuxuu dejin karaa jidka kormeerka ama isku xigxiga hal ama ka badan oo alaab ah | |||

| Daaqada navigation | Sawirka miiska ayaa lagu soo bandhigay shaashadda waqtiga dhabta ah, Guji meel kasta oo sawirka si aad u xakameyso dhaqdhaqaaqa. | ||

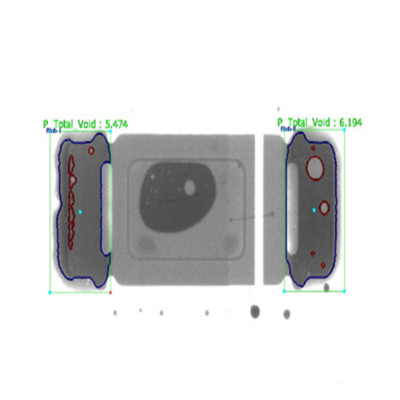

| Madhan cabbiraadda | Qiyaasta heerka faaruqinta | Qiyaasta buug-gacmeedka ikhtiyaariga ah, qaabka cabbiraadda hal/kubad-badan.Halbeegga aagga xumbo waxaa loo sii dayn karaa cabbir toos ah. | |

| Jiilka warbixinta | Natiijada xukunka si toos ah ayaa loogu calaamadin karaa sawirka, ama si toos ah ayaa loo soo saari karaa faylka CSV ama dukumeenti warbixineed iyadoo loo eegayo natiijooyinka falanqaynta. | ||

| Shaqada cabbirka | Cabbirka aagga | Heerka cabbirka aagga ee la sii dajiyay, shaqada degdega ah ee alaabta NG. | |

| Cabbirka cabbirka | Fogaanta, qalooca khadka dahabka, jiirada, xagal, iwm. | ||

| Xakamaynta dhaqdhaqaaqa | Meelaynta tooska ah | Awoodda miiska si otomaatig ah u shaqaynaysa, nidaamka dib u dejintiisa | |

| Imtixaan Dufcaddii | Soo rar barnaamijka wax-soo-saarka kahor si loo xaqiijiyo shaqada meelaynta tooska ah ee degdega ah, oo ku habboon kormeerka baaxadda weyn iyo maaraynta taxanaha alaabta | ||

| Beddelka goobta muuqaalka | Interface-ka ayaa si dhakhso ah loogu beddeli karaa inta u dhaxaysa 2 inch iyo 4 inches si loo xaqiijiyo labada shuruudood ee ogaanshaha ee goob ballaadhan oo muuqaal ah iyo indho-indheyn tafatiran oo qayb ah, badbaadinta wakhtiga ogaanshaha iyo hagaajinta waxtarka ogaanshaha. | ||

| Habka xakamaynta | Kantaroolka tooska ah ee CNC, kiiboodhka gacanta lagu hago, mouse, 3 hab waa ikhtiyaari. | ||

| Meelaynta caawimada | Meelaynta leysarka | Meelaynta laysarka dhibicda cas, kaaliye labanlaab ah, fududahay in la dhex maro | |

| Weyneeya navigation | Waxay ku kordhin kartaa dhibcaha ogaanshaha badeecada ee daaqada hagidda, taas oo ay fududahay in si sax ah loo helo loona hagaajiyo waxtarka ogaanshaha. | ||

Xakamaynta miiska

1. Xawaaraha miiska waxa lagu hagaajin karaa barta bannaan: hoose, caadi iyo xawaare sare.

2. X, Y, Z dhaqdhaqaaqa saddex dhidib ah iyo xagal u janjeedha waxa gacanta ku haya kiiboodhka.

3. Muqaal navigator weyn, sawirka navigation cad, miiska u dhaqaaqi doonaa meesha aad gujiso mouse ah.

Barnaamijyada CNC

Kaliya dhagsii jiirka oo waxaad qori kartaa barnaamijyo.

Shaxda shaygu waxa ay u socotaa dhinaca X, Y ee meelaynta;Tuubada raajada iyo qalabka wax sheeguhu waxay u socdaan jihada Z si loo meeleeyo.

Voltage iyo hadda waxaa dejiyay software.

Dejinta sawirka: dhalaalka, isbarbardhigga, helitaanka auto iyo muujinta

Isticmaalayaashu waxay bedeli karaan wakhtiga hakadka ee beddelka barnaamijka.

Nidaamka ka-hortagga isku dhaca ayaa kor u qaadi kara leexinta iyo u fiirsashada qaybaha shaqada.

Falanqaynta tooska ah ee dhexroorka, saamiga godka, bedka iyo wareega BGA.

Codsiyada X-RAY

Codsiyada X-RAY

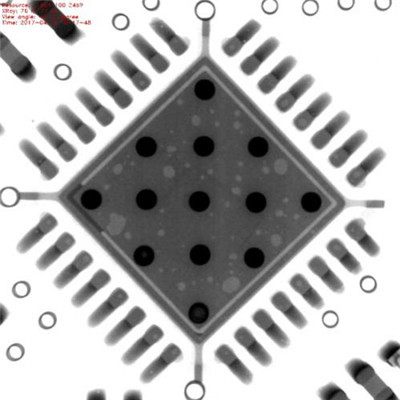

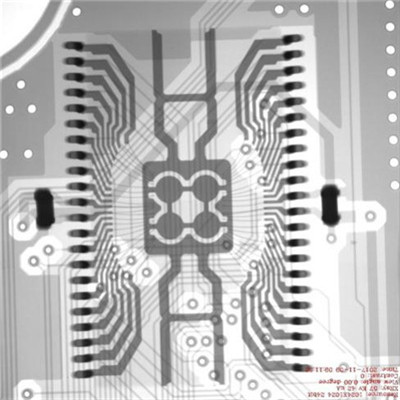

PCB BGA

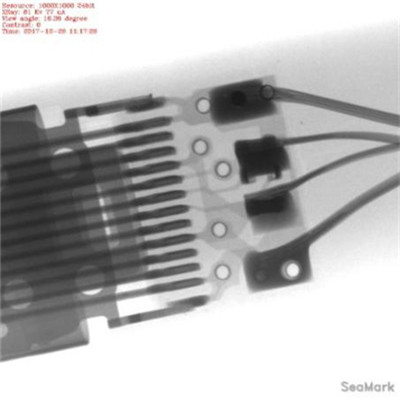

kamarada iPhone

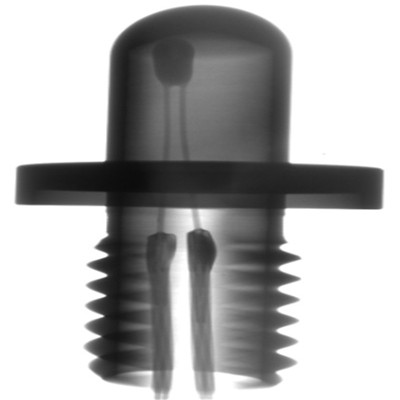

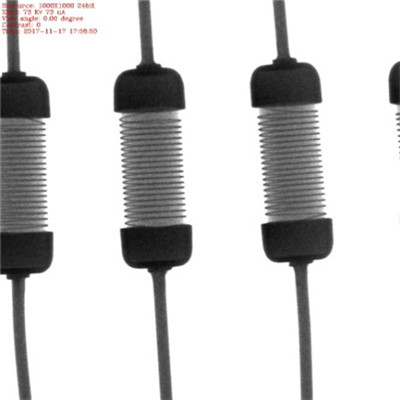

Diode

IC silig dahab ah

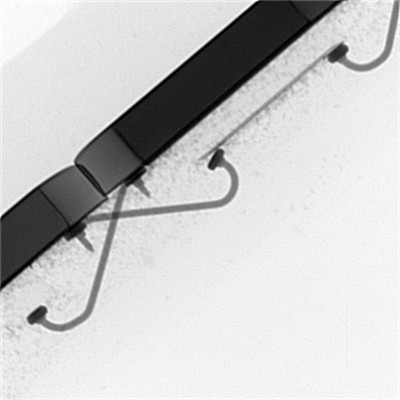

Xiriiriyaha

Fiilada isku xirka LED

IC madhan

IC madhan

iftiinka LED

Dareemaha kulaylka

awoodda Diode

Birta lagu iibiyo

Boodhka weyn ee iPhone

Chip silig dahab ah

Maqnaanshaha iftiinka LED

Awood sare semiconductor IGBT module

Xidhiidhiyaha dharka raaxada ma bannaana